Physical Requirements

Telecommunications Cabling Technician ( Inside plant)

This position is one of many

talents. It is a construction-oriented position. The technician will come in

contact with various cable types and must understand how to install, terminate

and test all of them. This technician should understand the industry standards

of installation as well as the National Electric Code. A good technician will be

familiar with various products to be able to make suggestions in different

situations and overcome adversity.

The Cabling Technician will travel to different locations and be

able to identify the different spaces and pathways for telecommunication

cabling. He or she will work with various hand tools in a construction

environment. He or she may be working in an existing office space or other

operating facility, which may require good customer relation skills, a

professional appearance and attitude.

A good portion of many projects is installing, placing or pulling the

cables to the various areas with in a building or campus environment. Climbing

of ladders is a routine task. Inspecting of drop ceiling areas, crawl spaces and

possibly manholes will also most likely be involved. This position requires

intellectual, physical and art skills.

Having your own hand tools, reliable transportation, a good driving record and a

positive work attitude will help one to excel in this career field

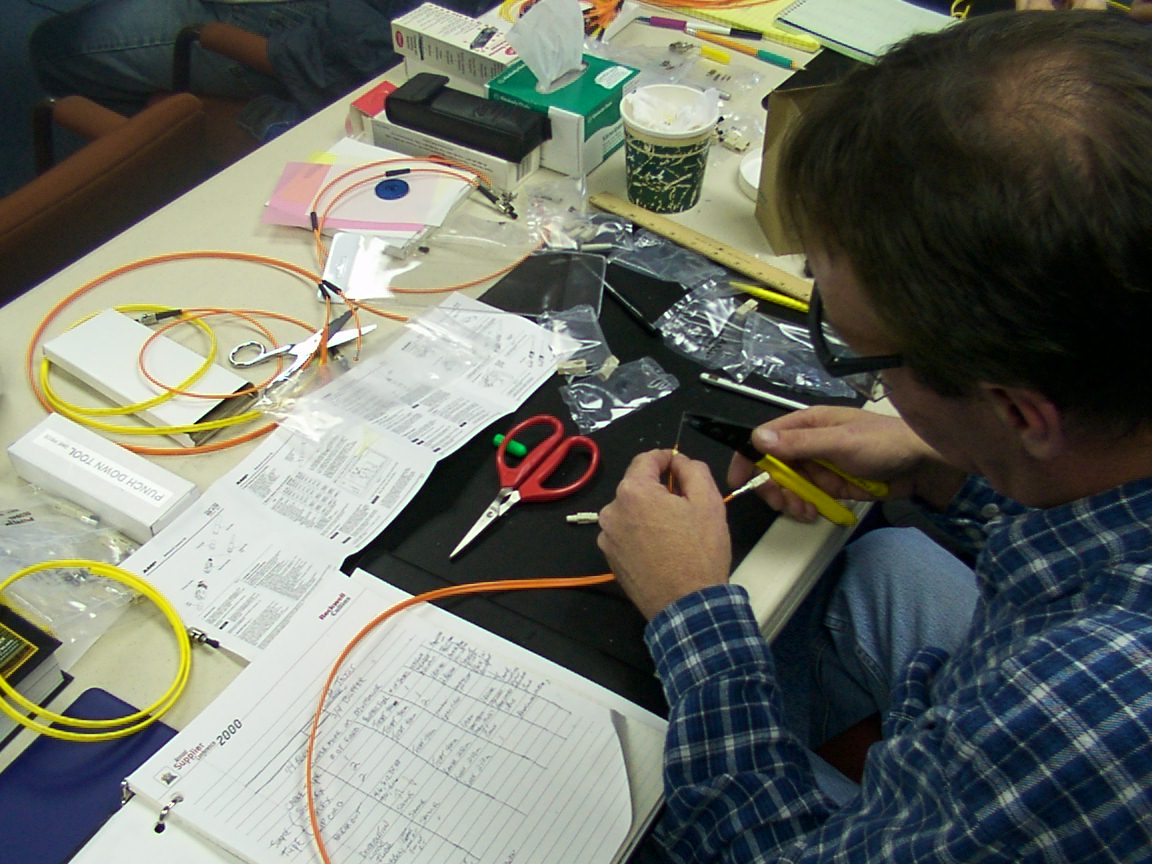

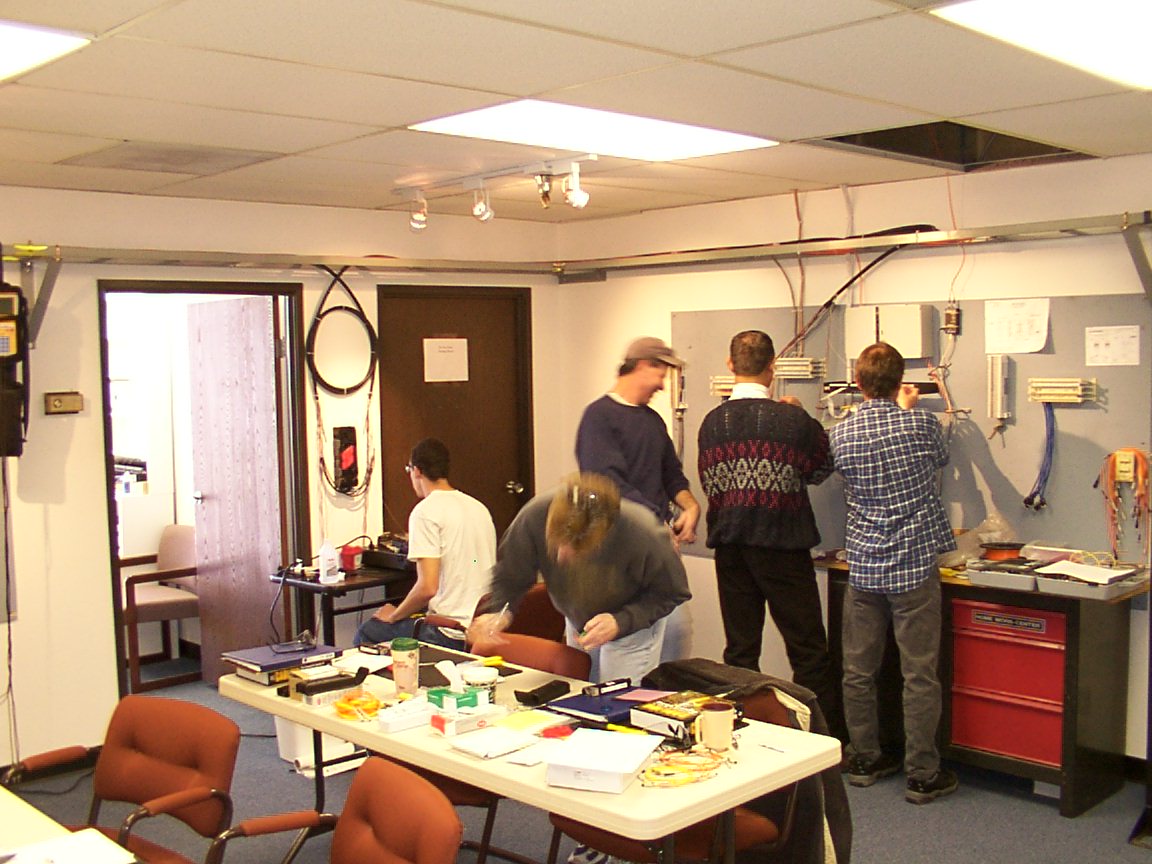

Terminating a fiber optic cable

Testing copper cabling

|

Splicing and testing fiber

|

Fusion splicing fiber optic cable

Student working on resume and job search

|

|

Click on the pictures for a

larger view. |

Fiber Optic Installer (Outside

Plant)

The fiber optic installer/technician is more physically demanding than an assembler's job however it is much less physically demanding than a telephone or copper cable installer. Fiber is light weight in comparison with copper cable. Pulling fiber cable off large reels is usually done with machinery. A back hoe machine digs up the fiber to ground level so the installer/technician can do his job. It usually means that he sits on the ground to repair the fiber. Digging trenches to lay the fiber is also done by machinery. The fiber installer generally works in his van to prepare the cable for installation. No heavy lifting is required. No standing or working in trenches is required. A machine lifts the cable out of the trench to ground level. Installers who work in buildings usually prepare and inspect the fiber cable on ground level using a

chair (to sit down) and some horizontal bench to lay the fiber. Fiber installers usually work in teams.

An installer may have varied jobs to do on site. One job may be to do fusion or mechanical splicing or work on a closure. This required no physical activity. Jobs in high-rise buildings may require some bending, but it is not continuous. Some climbing on short ladders or working below the floor board may also be required. The equipment used, depending on how old it is, can be as heavy as 40

pounds (Fusion splice machine), however in most cases the equipment is on a movable cart. Most equipment used today is computer based and much lighter then the older equipment. In other extreme cases, in long haul fiber installations, sometimes the trench dug out needs further digging, and the installer may need to use a shovel. An installer with a back injury in this case would probably have the other team

members do the digging.

Fiber Optic Assembler

(Manufacturing)

The fiber optic assembler, who sits at a table or bench, only needs to be able to see well. Corrective lenses are fine. In most cases a small microscope is required for inspection. Good manual dexterity would be a plus. The assembler gets up frequently to cut and measure the fiber, get connectors and test the cable. No heavy equipment is used.

A job analysis developed by a Rehabilitation Consultant and a Fiber Optic Company is available by contacting NCTC at

.